Highest precision for R&D and industry: SONOAIR® a quality leap in air-coupled ultrasonic testing

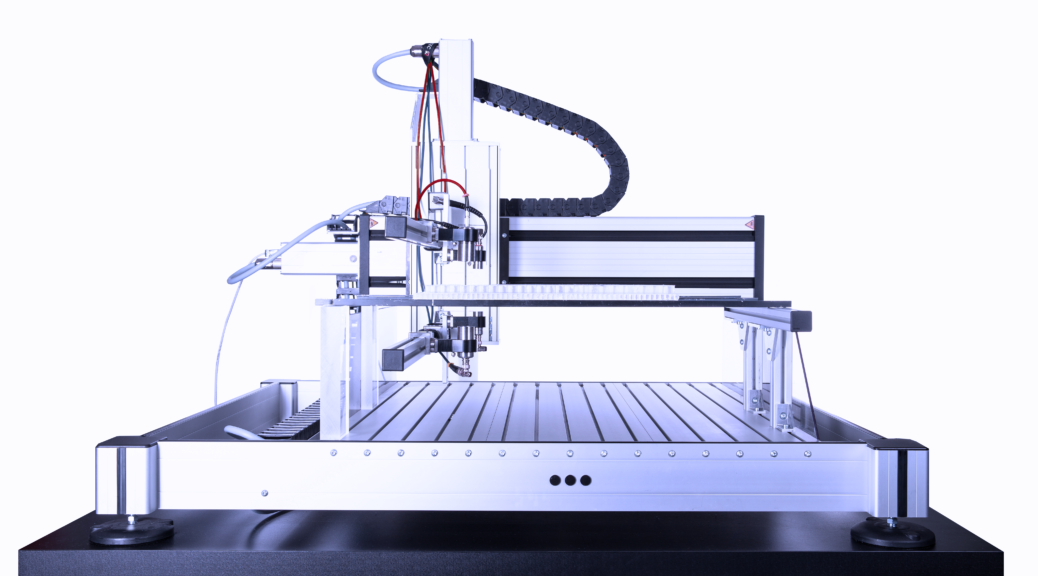

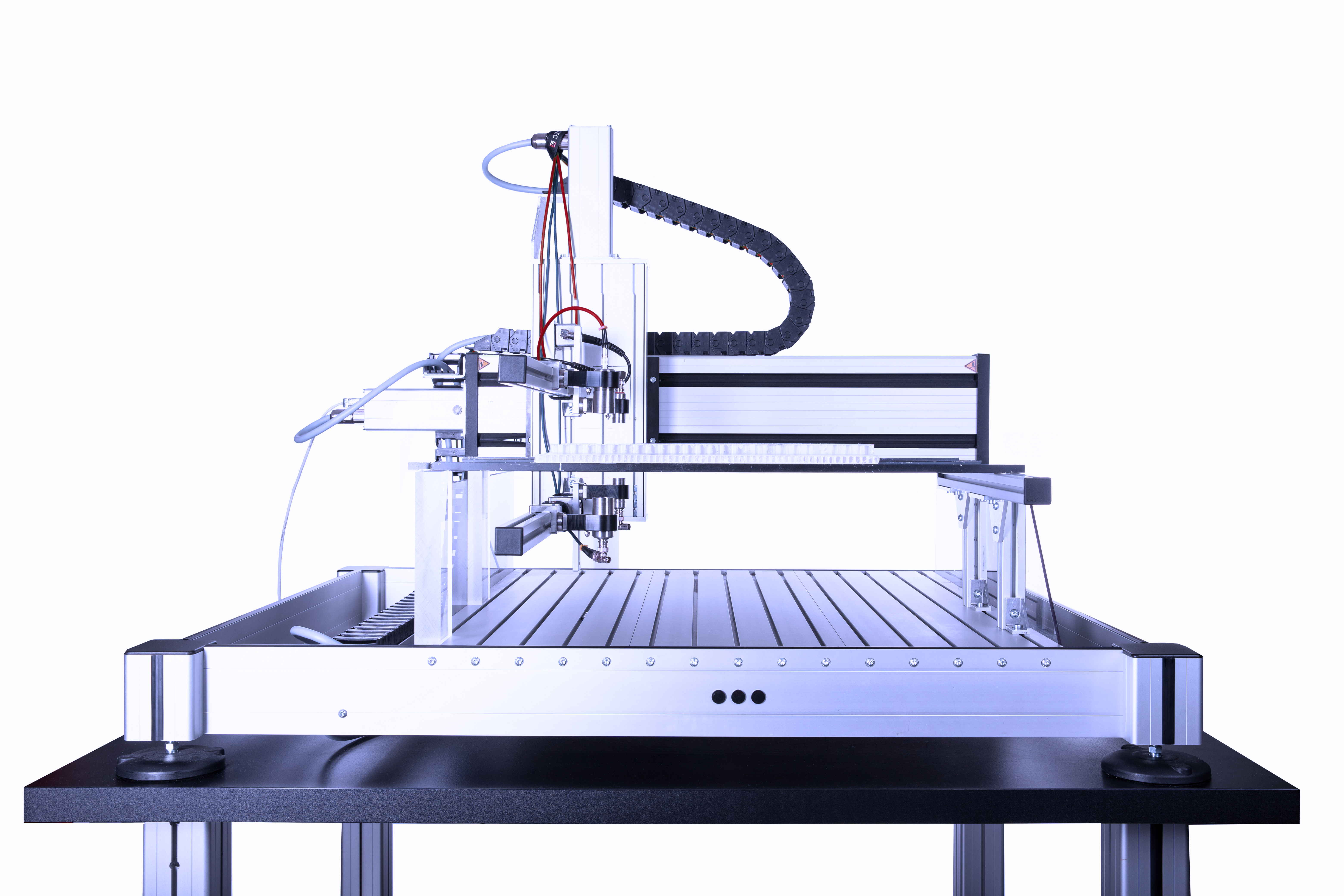

The SONOAIR® R&D turn-key solution consisting of a mechanical scanning system, highly sensitive probes, high-end laboratory electronics and R&D dedicated software is designed for the specific requirements of development and testing laboratories in universities, research institutes and pre-production industrial environments. Based on its state-of-the-art sensor design and production excellence, SONOTEC®, the international technology leader in air-coupled ultrasonic testing developed this next generation ultrasonic testing system in strong cooperation with the ultrasonic research center “Forschungszentrum Ultraschall” (FZ-U) – one of the globally leading institutes for air-coupled ultrasonic testing based in Halle (Saale), Germany.

The SONOAIR® R&D system is capable to detect the most common discontinuities in test objects where the use of conventional liquid coupled ultrasonic testing systems is not possible. Especially multi-layer glass and carbon fiber composites with foam or honeycomb cores can be inspected for delaminations, air inclusions, kissing bonds or impact damages. Efficient and reliable air-coupled ultrasonic testing of plastics, ceramics, concrete, wood and other structures is also possible with the SONOAIR® system.

Highest accuracy in non-contact ultrasonic testing

„Our technology is a lot more sensitive and can provide a higher resolution, than other air-coupled ultrasonic testing systems which have not been developed further over the past years, to find even small defects in thicker and highly attenuating materials.”, says SONOTEC Managing Director Michael Münch. The outstanding sensitivity results from the very high transmission power of the pulser electronics of up to 800 Volts in combination with an unmatched amplification process of the received signals and an extremely low noise level of less than 1 nV/√Hz.

“With a noise level as low as thermal noise the smallest signals can be amplified to generate clear and reproducible measurement results even for highly attenuating materials. This is what makes the SONOAIR system the new benchmark for non-contact ultrasonic testing.”

Samples that were previously considered not testable with ultrasound can now be inspected reliably. In addition, a classification of flaws such as the quality level of an adhesion can be determined. Conclusions can also be drawn from deviations of the signal shape to characterize the specific nature of defects. Due to the lack of liquid couplant the inspection process is considered to be fast and cost efficient.

Software designed for special user groups

SONOWARE Basic was designed for a comprehensive and efficient use in laboratories. The collected data can be evaluated via A-, C- and D-scan images. SONOWARE also provides a wide selection of post processing tools such as filters. The extended SONOWARE Advanced version is intended for the development of individual analysis and evaluation methods. The full raw data can be accesses and exported to external software such as MATLAB or LabVIEW.

SONOTEC® offers advanced application consulting, training and project support pre- and after sales. As an addition to the product family, a SONOAIR® Industrial version designed for integrators as an essential part for in- and offline production applications will be available soon.

Originalmeldung von pressebox.de